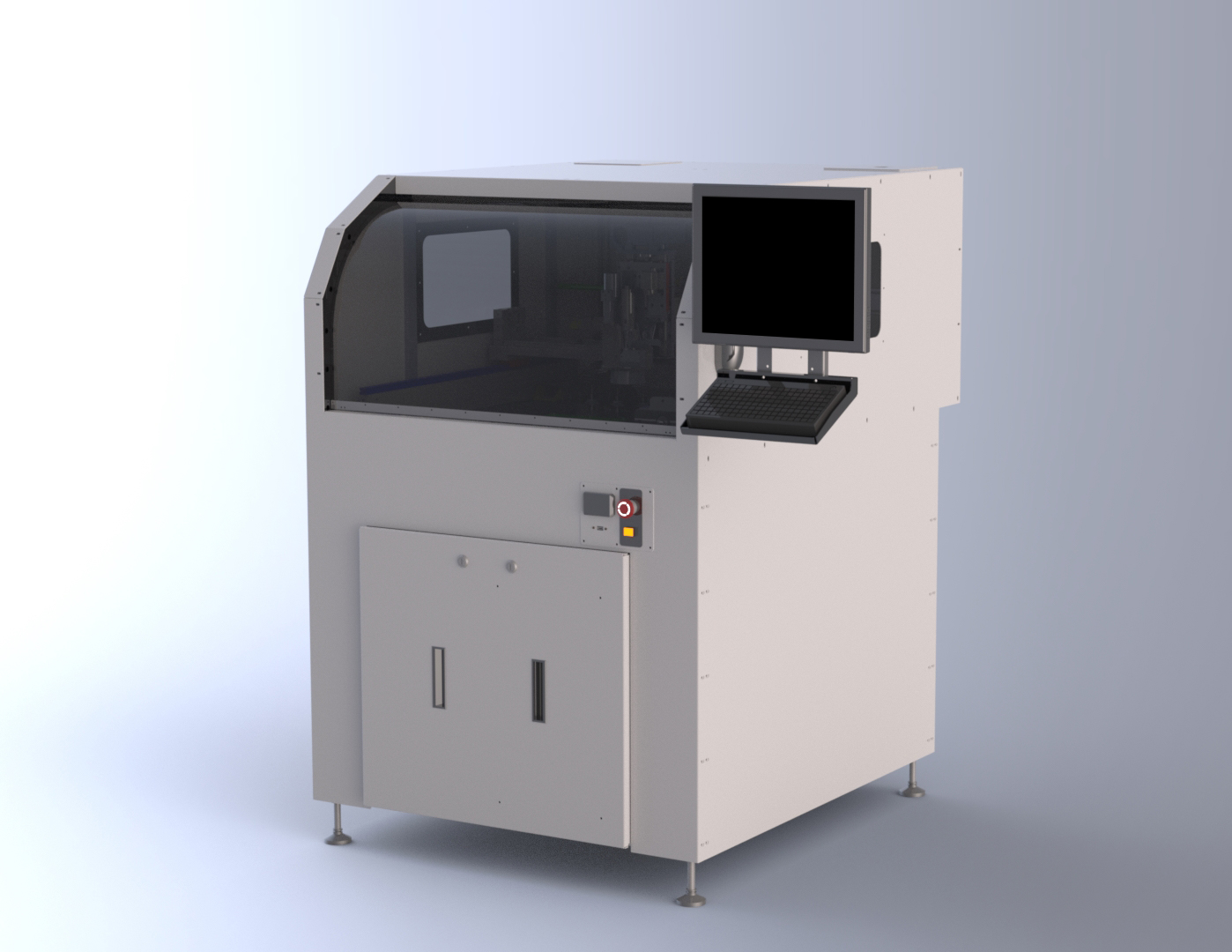

MR2

Product Features

The MR2 has heavy duty machine tool construction. It’s primary mounting base is made of solid two inch thick steel and is precision ground. Its base construction supports its high precision (cutting accuracy .0005 inches) and high speed movement capabilities. The MR2 has an overhead gantry utilizing the highest precision THK ball screws and closed loop servo drives. It is capable of making a full range of cut types including: lines, arcs, angles and 3D topography. The MR2 has a bottom side vacuum plenum as large as the full PCB with an additional optional top vacuum. The dual vacuum configuration produces unequalled debris removal.