Custom vs. Ready-Made: How You Can Find the Middle

By: Patrick Wolfe

In a world where you can customize the shirt you’re wearing, the car you’re driving, and anything in between, companies feel a push to become more customizable. Making products that are fully customizable could be very difficult in many situations, on the other hand only making “ready-made” products could be hurting your sales as well.

Many pros and cons arise from both, let’s compare and contrast.

Length of the process

It seems that today, people are losing patience quicker than ever. When building custom machines you have a long lead time from 6 weeks to 6 months sometimes. So you can imagine how impatient a customer could get. But ready-made machines means you could build up stock or skip the design phase altogether and you’ll be saving your customer some frustration.

Costs

Just using the word “custom” you will be able to sell at a higher price point. This means more profit for you, but higher cost for the customer. Even better, there aren’t any upfront costs, but it has the potential to be more expensive to build than a typical ready-made machine depending on the customizations. On the other hand, ready-made machines have more upfront cost due to the building of stock without any actual customer orders. However, they would be costing the same price every time.

Flexibility and Customer Retention

Customers want machines that fit their needs to a T. So naturally they would need or want a custom machine that is tailored to them and their needs. Not to say that some customers won’t be perfectly fine with a simple ready-made machine, because some of your customers will. Usually, customer retention is higher when buying custom machines. Really, who could blame them? That machine is exactly what they need and it gets the job done, therefore, customers are going to come back.

Storage and Surplus.

If you build a surplus, you need a place to put it- plain and simple. This could be a con for some and a pro for others. If you’re building custom machines storage isn’t an issue. In contrast, having a surplus is great and when you have a lot of sales you’ll have the inventory to back that up. With custom machines, there is almost no way to stock up and build an inventory.

Errors

One big problem you might run into while building a custom machine is errors, whether it’s due to a new design, new technology, or a new process. Things can always go wrong, but the likelihood of it happening is great while building custom.

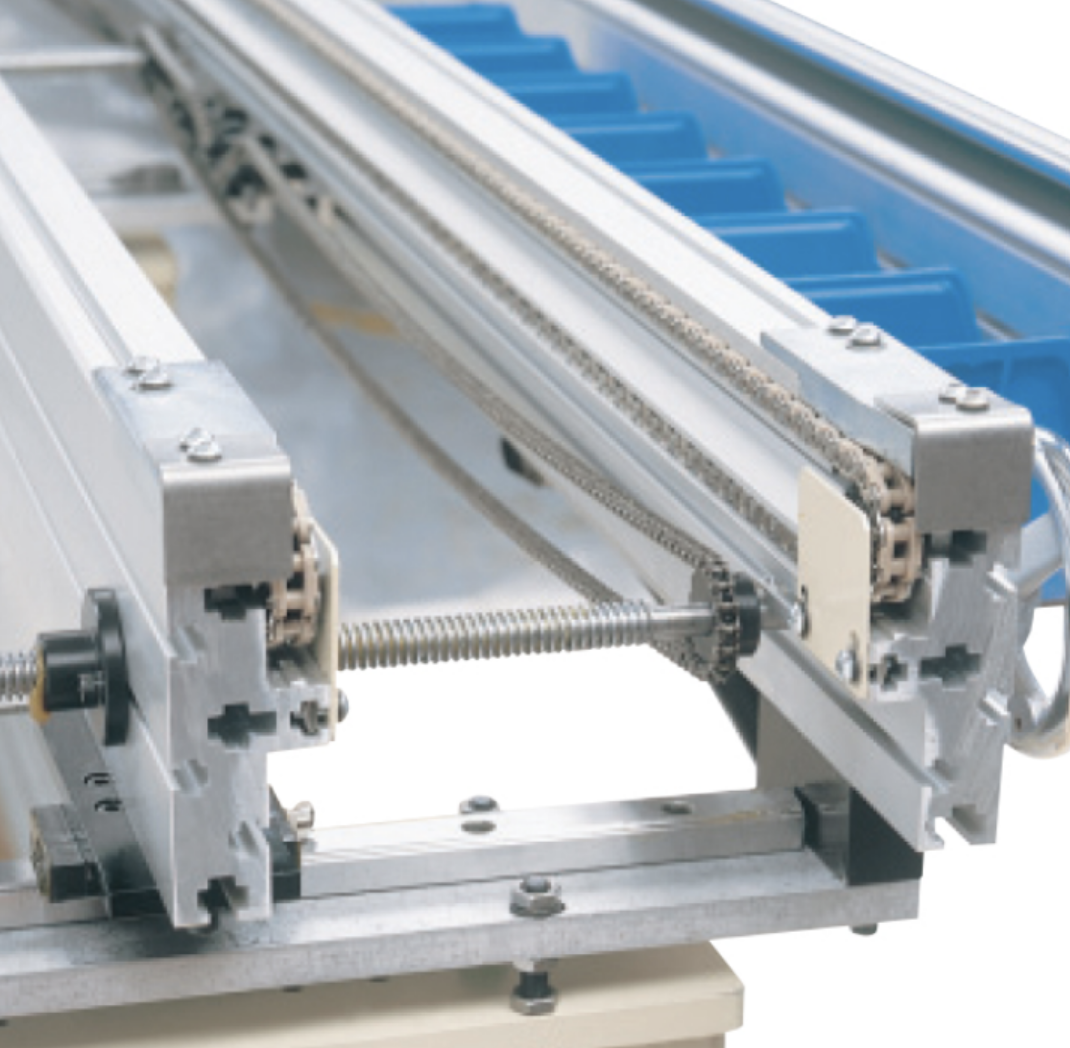

80/20

80% ready-made 20% custom. So, you have options for the customer for things they would need to change and the rest you already have laid out. If you make options too limited then it’s just a ready-made machine, and if you give them too many options then it’s just a custom machine. To put it simply, when you buy a pizza it’s small, medium, or large. You get to choose the toppings. There are base models and then you choose your options.